Previously, we were only able to work and test our hypothesis on parts of the project. Now that all parts have arrived it is time to put everything together and apply all that we have found out during the previous phase.

We finally embark on our experimenting phase!

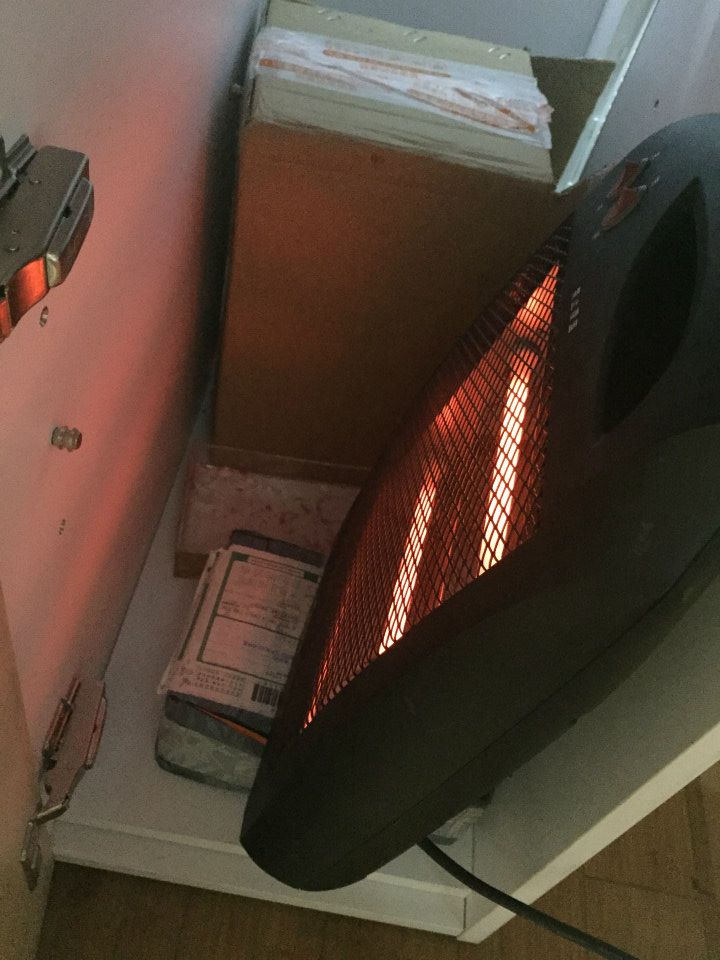

Before the first experiment even started, we ran into trouble. We had to prepare an anti-stick layer on the resin bath, which brought equipments like vacuum desiccator and analytical balance into the equation. But clearly being a design college, there is no place for such equipments!

But with numerous failures and wasted Sylgard, we managed to create acceptable PDMS layers without all those complicated scientific equipment.

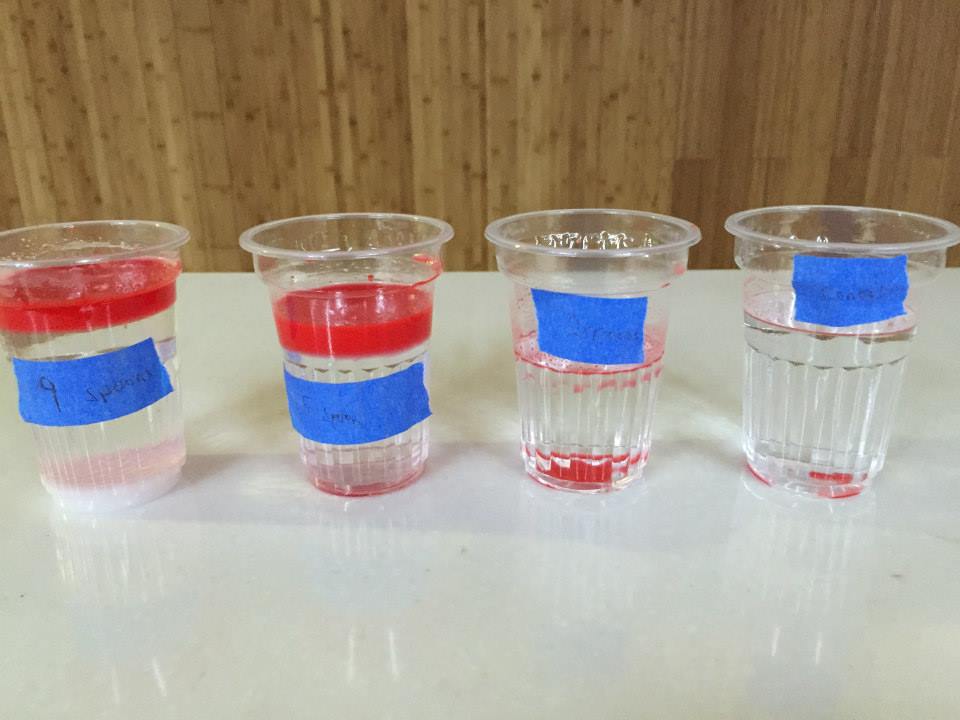

We first had to scale the projected image on the resin to the true size of the CAD object. This was more troublesome than it sounded and it took us lots of effort and patience just to get it to print to the correct X-Y scale. More effort and patience was expanded to get it to print to the correct Z scale.

Effort and patience was in short order and then…

Things started getting printed.

The integration of hardware and software went smoother than we expected. No critical issues popped up, problems we had expected with the peeling aspect of SLA printing process did not happen.

In short, it was ‘All green, all systems go!’

With the new knowledge gained through our experiments from the first printer, we begin to work on our second revision.

Stay tuned for updates on revision 2.

Felix Soo

Engineering Product Development