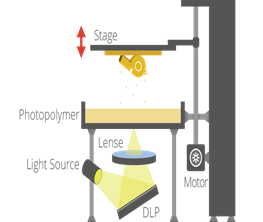

Baby Steps Hello all! This will officially be the first post by the SLA 3D Printer Team! The primary goal of our team would be to design a SLA 3D Printer by the end of this exchange. So…. What is a ‘SLA’ 3D printer? SLA stands for Stereolithography which involves the use of UV light to cure materials. Most of us are familiar with our school’s Fused Deposition Modeling (FDM) 3D printers.

Fundamentally, the material used is different (resin for SLA & thermoplastic for FDM) along with the method of creating layers. Each printer has its advantages and disadvantages though FDM printers are more commercially used while SLA printers are often used by industries due to their high cost. Such a project begets a question… where do we begin? Preliminary research reveals that there is so much to consider when trying to create a 3D printer. There are both hardware and software considerations when designing the printer. Axis mechanisms, projector types, choice of resin are all classes of research by their own right! Along with OpenGL/OpenCv coding requirements, such a project is rife with complications to green undergraduate students such as ourselves! Thankfully, our professor has associates at Tsing Hua University (Beijing) and they have graciously allowed us to use their blueprints and code. They even invited us over to have a look at their completed prototype for us to compare with our own. But before we set off for Beijing, our team scanned through the blueprints and code. We spent a few days ordering the parts required as well as researching for existing precedents. It was truly a remarkable first week as we were suddenly exposed to many technical terms and practical considerations in design. Part of the challenge was to consolidate together our research and determine which aspect of the 3D printer held the highest priority. 10 weeks is an extremely short amount of time and it would be impossible for us to look into every single aspect for improvement. To make full use of our time here in China, we should dedicate more man-hours into the more important aspects. Once the parts arrived it was time to assemble the 3D printer! Naturally, we expected many problems to surface during this phase. Holes of the wrong size, non-threaded holes, tight fitting plates, wrong screws etc. Such problems were simple and common and yet they severely hamper our assembly process. If we were to recreate our own 3D printer, we need to be absolutely sure of the details before we send in the parts for manufacturing.

Fundamentally, the material used is different (resin for SLA & thermoplastic for FDM) along with the method of creating layers. Each printer has its advantages and disadvantages though FDM printers are more commercially used while SLA printers are often used by industries due to their high cost. Such a project begets a question… where do we begin? Preliminary research reveals that there is so much to consider when trying to create a 3D printer. There are both hardware and software considerations when designing the printer. Axis mechanisms, projector types, choice of resin are all classes of research by their own right! Along with OpenGL/OpenCv coding requirements, such a project is rife with complications to green undergraduate students such as ourselves! Thankfully, our professor has associates at Tsing Hua University (Beijing) and they have graciously allowed us to use their blueprints and code. They even invited us over to have a look at their completed prototype for us to compare with our own. But before we set off for Beijing, our team scanned through the blueprints and code. We spent a few days ordering the parts required as well as researching for existing precedents. It was truly a remarkable first week as we were suddenly exposed to many technical terms and practical considerations in design. Part of the challenge was to consolidate together our research and determine which aspect of the 3D printer held the highest priority. 10 weeks is an extremely short amount of time and it would be impossible for us to look into every single aspect for improvement. To make full use of our time here in China, we should dedicate more man-hours into the more important aspects. Once the parts arrived it was time to assemble the 3D printer! Naturally, we expected many problems to surface during this phase. Holes of the wrong size, non-threaded holes, tight fitting plates, wrong screws etc. Such problems were simple and common and yet they severely hamper our assembly process. If we were to recreate our own 3D printer, we need to be absolutely sure of the details before we send in the parts for manufacturing.

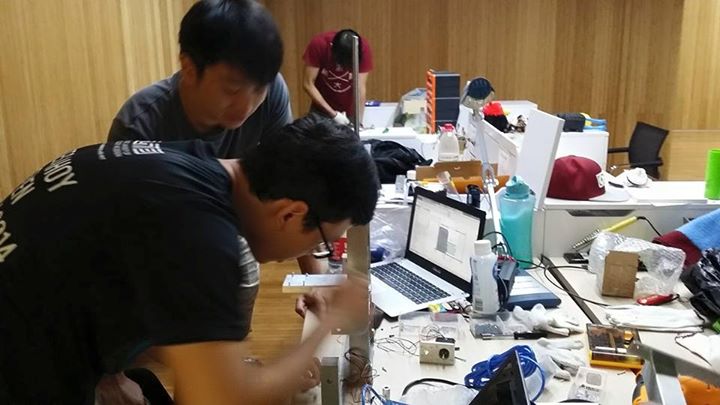

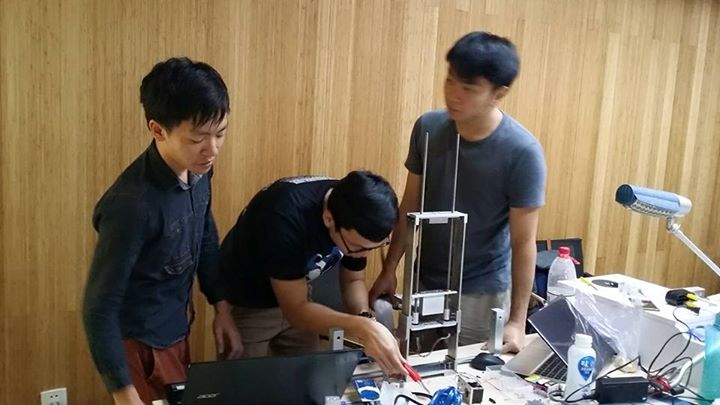

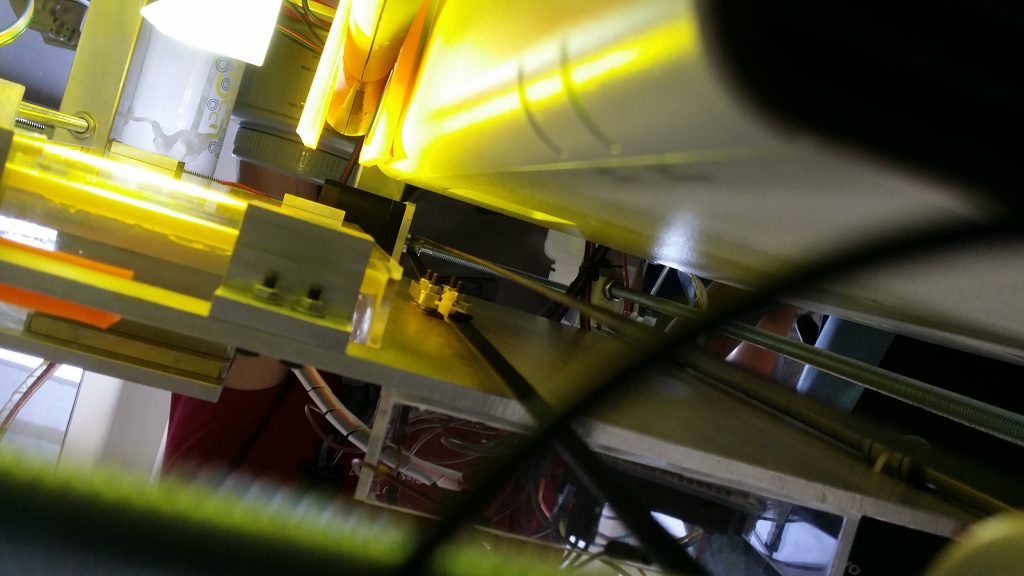

The Assembly

How many undergraduates does it take to design a 3D printer? 4!

Satellite Fab Lab @ ZJU! Everyone hard at work!

Satellite Fab Lab @ ZJU! Everyone hard at work!

Efficiency at its finest! Two guys look at a guy doing stuff while the fourth guy takes a photo of them!

Efficiency at its finest! Two guys look at a guy doing stuff while the fourth guy takes a photo of them!

THIS BOY IS ON FY-REEEEEEEEEEEEEE~

THIS BOY IS ON FY-REEEEEEEEEEEEEE~

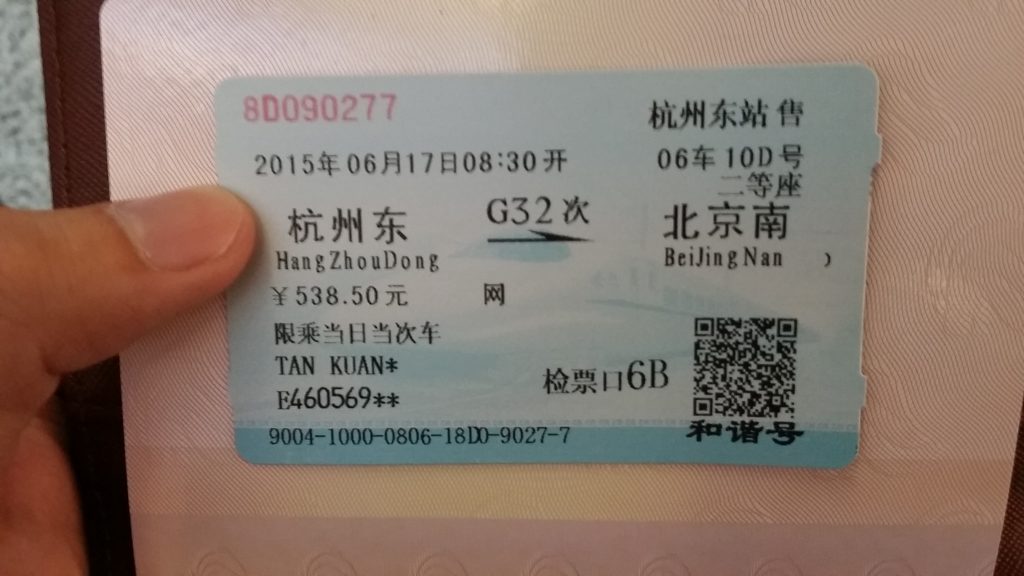

500 Yuan in our hands

500 Yuan in our hands

Harmony the EM Train!

Harmony the EM Train!

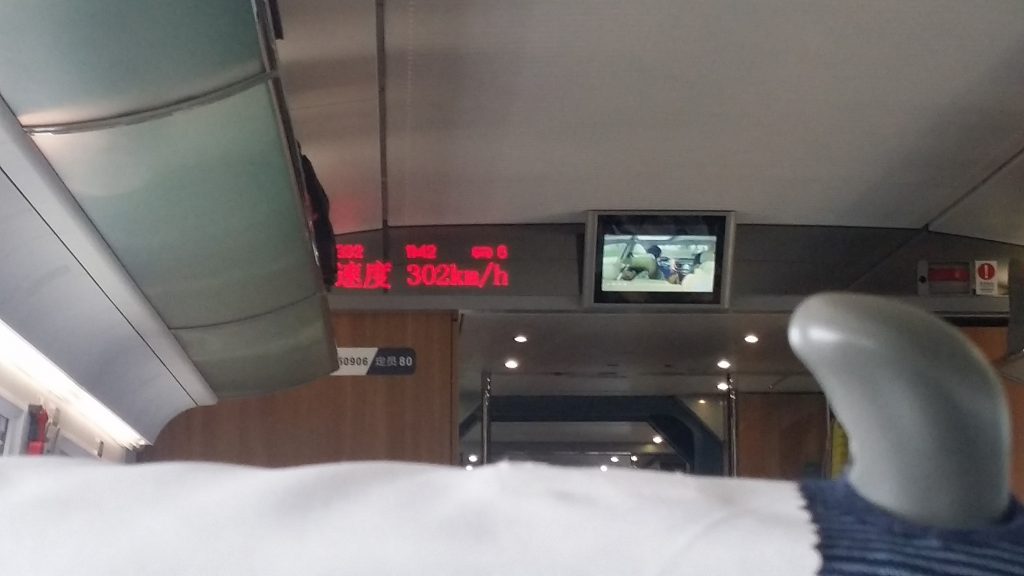

THIS TRAIN IS ON FY-REEEEEEEEEEEE~ (302km/h!)

THIS TRAIN IS ON FY-REEEEEEEEEEEE~ (302km/h!)

Say hello to normal subway train!

Say hello to normal subway train!

Our accommodations at Home Inn!

Our accommodations at Home Inn!

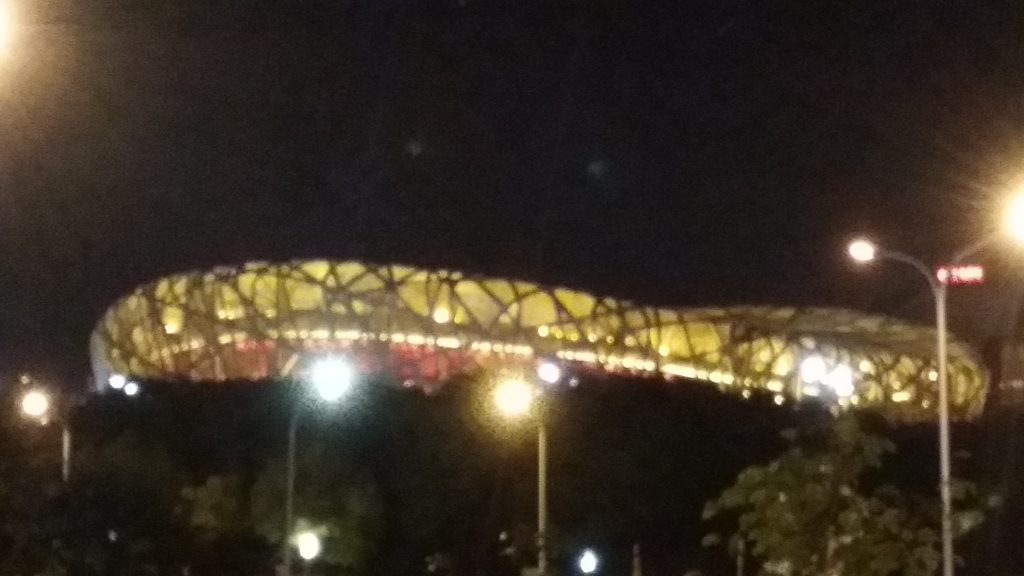

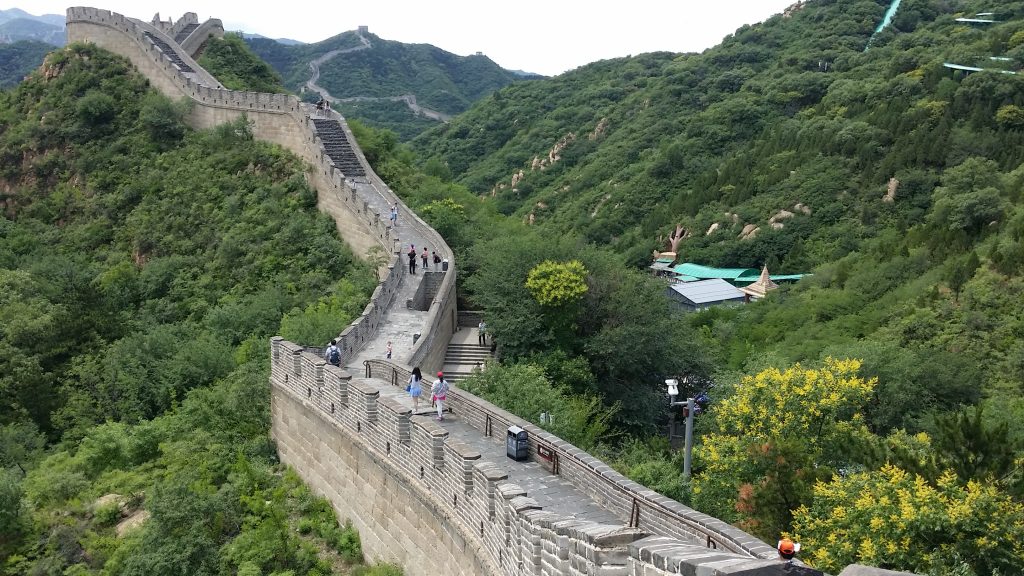

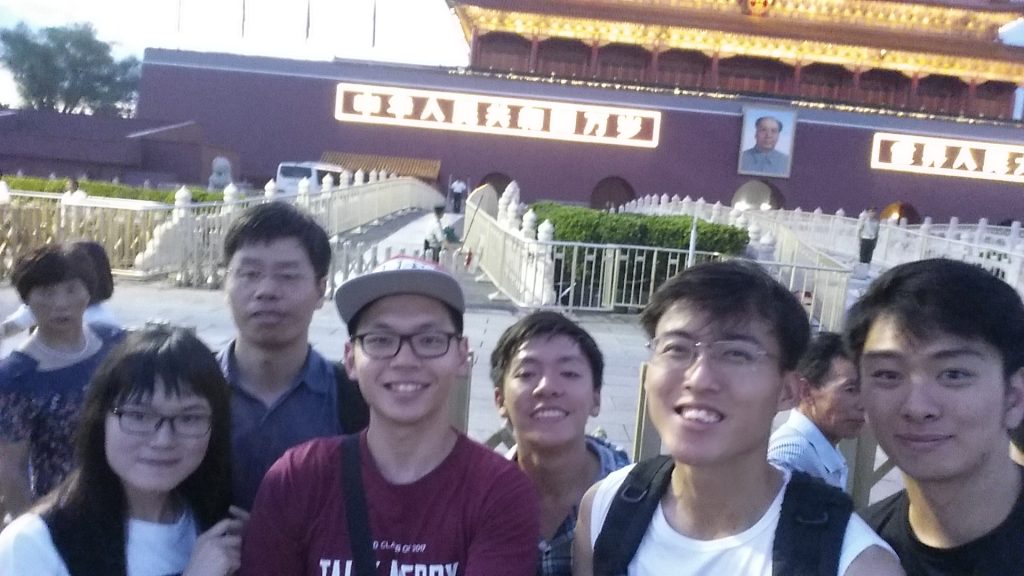

Tian An Men and the Forbidden Palace

Tian An Men and the Forbidden Palace

Time to rest… But first… Let me take a selfie~

Time to rest… But first… Let me take a selfie~

With random photobombers at the back!

Tsing Hua University!

Tsing Hua University is one of China’s most renown universities, alongside Bei Da University. It was an honor for us to be able to visit this university, thanks to the courtesy of our professor!

Tsing Hua University is one of China’s most renown universities, alongside Bei Da University. It was an honor for us to be able to visit this university, thanks to the courtesy of our professor!

Unfortunately we are not able to go into details of the 3D printer for now as it strictly belongs to Tsing Hua University. So stay tuned for me information!

Unfortunately we are not able to go into details of the 3D printer for now as it strictly belongs to Tsing Hua University. So stay tuned for me information!

In the mean time…