I have recently embarked on an Undergraduate Research Opportunity Program (UROP) which is conducted under Dynamic Assemblies Lab and Functional Textiles group, and is led by Assistant Professor Kenneth Joseph Tracy (ASD)(Principal Investigator). It is titled Tensegrity and involves an architectural structure built with principles of compression and tension. I have been under the guidance of Research Assistant Chia Pei Zhi (DmanD).

The basic idea of the UROP stemmed from a group of DmanD researchers who are in collaboration with some professors from the ASD Pillar, who wish to participate in an upcoming structural competition in Barcelona. I was interested in this UROP as I thought it would provide me with an opportunity to gain some exposure to materials science, which was an area of my interest.

For the past month or so, I have been helping in small ways such as via data collection, data analysis and the production of some small mechanical parts. This includes laser cutting washers or struts for the prototype structures, and measuring specifications of the prototypes that the researchers had created before observing if there are any trends or patterns in the numbers.

With regards to the washers, I had to laser cut a small whiteboard as this was the material requested. As the washers were extremely small (inner hole diameter of 0.7mm and external diameter of ~5mm), I had to use a base plate to prevent the washers from simply falling through the grid at the bottom of the cutter. Below are some supporting photographs:

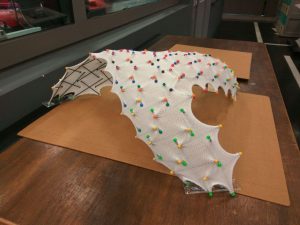

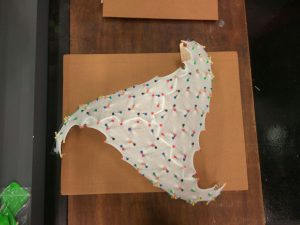

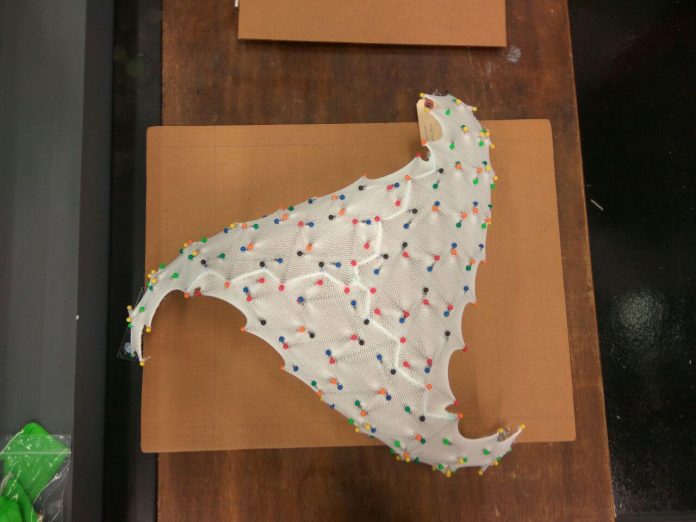

The more challenging part was the data collection and analysis. While the data collection was simple, it was tedious as there were 32 sets of readings to take for each of the (total 2) materials of prototypes. There were horizontal, horizontal-diagonal, vertical and vertical-diagonal chord measurements to take, and also the heights of the curves at each of these directions. Here are some images of the prototypes:

While most data did not show a noticeable trend, it was note-worthy that the curvature of the prototypes were larger consistently for the direction perpendicular to the direction of the strut that was inserted first. Basically, the prototypes followed logical geometric rules.

To end off, here are some photographs of other larger prototypes of tensegrity structures that the researchers had created in order to plan for their final product (which will be a 2-metre tall equivalent of something similar). As this UROP develops further, I will continue to share my learning through journals on this blog. If you are interested, do keep a lookout for Tensegrity-tagged posts!