In the face of a growing climate crisis, SUTD scientists take an innovative, avant-garde approach to sustainability research.

From Storm Eunice in Europe to deadly flooding in Australia’s New South Wales, the chaos brought by climate change is becoming a norm. Even in Singapore, the current wet season is proving to be wetter than usual, easily submerging large swaths of the country. Indeed, as climate experts have pointed out, we are already going through the climate crisis.

All hope is not lost yet. It’s still possible to soften the blow of the environmental crisis, even if just slightly, provided we take concrete actions now. One critical approach to achieve that is through sustainability, which refers to finding ways of meeting everyone’s needs – such as food, housing and adequate jobs–without leaving the planet uninhabitable for future generations. Since it was first introduced in a 1987 UN report, the sustainability movement has gained a large number of supporters worldwide.

Responding to the global clarion call for building a more sustainable society, the Singapore University of Technology and Design (SUTD) released its new and inclusive Sustainability Plan (SSP) in December 2021. The plan banks on design thinking, technological innovations and collaborations with community and industry.

While the SSP is a detailed and intricate document, at its core are key commitments by the SUTD to ramp up research on sustainable products and potential software solutions. SUTD is also transforming the campus itself into a living experimental ground to test-run budding and promising solutions. Here, we take a look at just a few of the most exciting sustainability innovations at SUTD.

Ushering in the ‘Biomaterial age’

In order to push the limits of sustainable material research, the field itself may need to undergo a fundamental shift, particularly in terms of manufacturing.

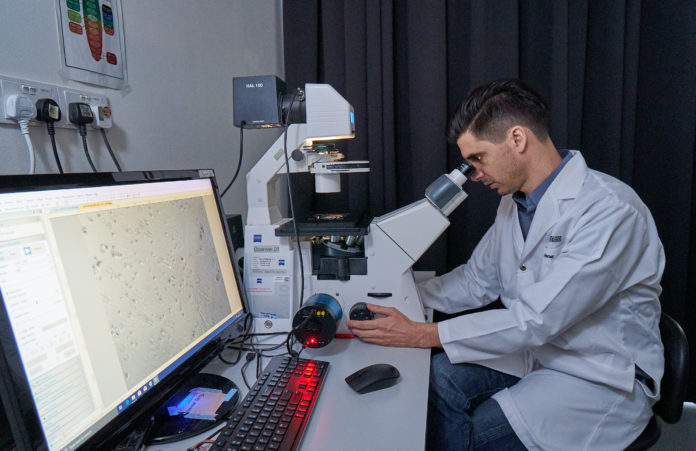

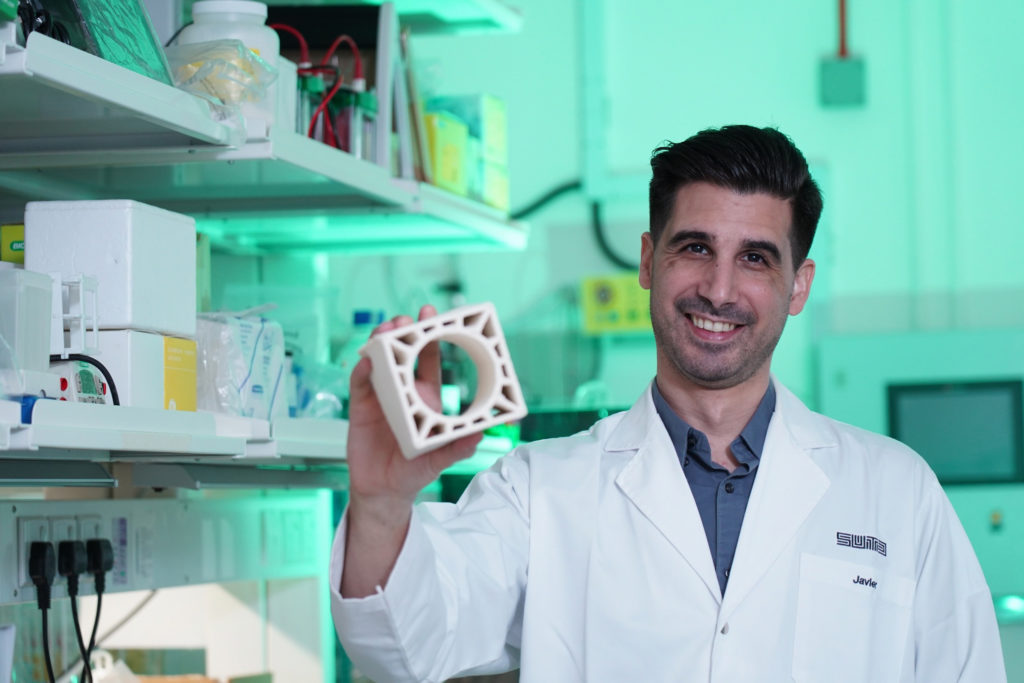

“The use of biomolecules by humans has been focused on adapting them to technologies conceived for other types of materials,” explained Dr Javier Fernandez (pictured above), Associate Professor at the Engineering Product Development Pillar at SUTD. “By doing so, we are also removing those molecules from Earth’s ecology.”

Take plastics, for example, which come from crude oil and natural gas. Because the plastics undergo extensive processing, their properties are altered, giving rise to products that are out of step with nature’s degradation cycles, ultimately becoming pollution after use.

At The Fermart Lab, which Assoc Prof Fernandez leads, the philosophy is to harness the inherent properties of natural molecules rather than to transform them. “We use unmodified natural components and develop manufacturing technologies based on the biological principles under which those molecules are assembled,” he said.

This approach has allowed the lab to develop fungal-like additive materials (FLAM), one of the most viable alternatives to plastic to date. Made from unmodified chitin and cellulose, the two most common natural polymers on the planet, FLAM is completely biodegradable and ecologically sustainable. It can also match the versatility and utility of synthetic plastics.

This approach has allowed the lab to develop fungal-like additive materials (FLAM), one of the most viable alternatives to plastic to date. Made from unmodified chitin and cellulose, the two most common natural polymers on the planet, FLAM is completely biodegradable and ecologically sustainable. It can also match the versatility and utility of synthetic plastics.

Moving forward, Assoc Prof Fernandez understands the importance of making their bioinspired manufacturing easy to adapt, so as to usher in what he and his colleagues at The Fermart Lab call the “Biomaterial age.” In fact, they have already successfully integrated their novel manufacturing process into food waste management and other local production systems.

Opportunity in food waste

Efficient use of food waste is also a top priority for Dr Leo Chen Huei, Assistant Professor at the Science, Mathematics and Technology Cluster at SUTD. After all, more than 10 percent of all of Singapore’s waste comes from discarded food. In 2020, the country produced more than 650,000 tonnes of food waste, enough to feed every person in Singapore an additional 1.5 bowls of rice per day.

To help tackle the problem, Asst Prof Leo is repurposing fruit waste by extracting bioactive compounds from the waste and turning them into something useful such as nutraceuticals or skinceutical products. In another example, together with Dr Michinao Hashimoto, Associate Professor at the Engineering Product Development Pillar at SUTD, orange peels were 3D-printed to produce food with aesthetically pleasing structures, turning waste back into something fit for consumption. Collaborations like this are central to Asst Prof Leo’s push to cut back on food waste.

Ugly Food, founded by SUTD alumni, is a social enterprise that aims to promote sustainability by reselling food that other supermarkets rejected due to simple blemishes or skin-deep imperfections. Despite such efforts, unavoidable food waste such as seeds and peels is inevitable.

“This is an area that our work can contribute to further close the loop on the food waste, where we can use science and technology to upcycle these unavoidable food waste,” said Asst Prof Leo.

Ultimately, the efforts of Assoc Prof Fernandez, Asst Prof Leo, and Assoc Prof Hashimoto fall in perfect step with SUTD’s mission to produce creative, mold-breaking, and inter-disciplinary research that matters to society.

After all, “we won’t reach sustainable development walking the same path that brought us here,” said Assoc Prof Fernandez.